| The Peterhead whaling trade |

|

Home |

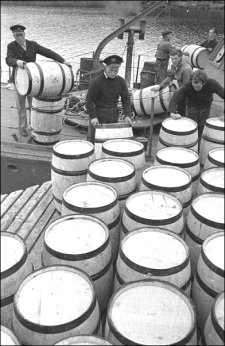

Making off - putting the blubber into barrels Blubber had to be boiled to extract its oil. The American whalers often did this on board ship, whilst still at sea, but the British Greenland whalers always brought the blubber back to port for processing. Whilst there were whales still to be killed, blubber was simply piled up in a convenient space in the hold, known as the flens-gut. Once they ran out of space, or when there was a lull in the killing, the whaling crew started the process of making-off (from the Dutch afmaaken, meaning to finish or complete). This involved freeing the fat of skin and any bits of muscle, cutting it into small pieces and putting them into casks through the bung-holes. For making-off the ship was moored to a convenient ice-floe and the sails furled. Then the whole crew got to work, most on deck but a few in the hold under the supervision of the skeeman, the hold officer. The whole process was highly organised with different categories of the crew taking on specific responsibilities. On deck, the speck-trough, a box 12 feet in length, 2 feet wide and 2 feet deep, with a square hole in its bottom, was placed over the hatch leading to the hold. Attached to the trough were tables covered in chopping boards made from whales' tails. The blubber was thrown from the flens-gut up onto deck where crew members known as krengers removed any muscle. From the krengers, the blubber was passed to the harpooners who sliced off the skin. From the skinners the blubber passed to the chopping boards where the boat-steerers, armed with chopping knives, cut it into oblong pieces less than 4 inches in diameter. Finally, the blubber was thrown into the speck-trough to fall back into the hold. There, the line-managers (the men who were in charge of the harpoon lines during the hunt) fed the pieces into the bung-holes of the casks. The casks, once tightly filled with blubber, were securely bunged-up. Fifty skilled men could process about 3 tons of blubber per hour. The hold was packed with several tiers of casks and filling, moving and arranging them must have been a stinking, 3-dimensional, logistical nightmare for the skeeman. If the ship was so successful in the hunt that it ran out of barrels, then slabs of blubber were laid, skin down, on the top layer of barrels and scattered with salt. Once the hold was full, or the season at an end, the ship made for home, as rapidly as possible, and hoping for cool weather once it left the ice.

|